Materials and Finishes

Choose the finish that best suits your style, and familiarise yourself with the material that is best suited to your environment.

Ongoing care and maintenance will ensure the longevity or your PO Box product. Different materials require different levels of care, and the frequency of maintenance will vary according to your location and environment. Coastal areas require more maintenance than others, and please note that rusted finishes when exposed to moisture will leach onto surrounding surfaces.

Standard Material Options

Corten

(Rusted)

Standard thickness selection –

1.6mm & 3.0mm

Maximum sheet size –

3000x1200mm

Corten is an architectual rusting steel designed to rust. It has a copper content, and its chemical makeup differentiate it from regular mild steel in that it is designed to build an outside layer of rust that protects the core material. Its copper content ensures that the core material will not deteriorate and you can expect a very long life from Corten steel.

Corten requires no ongoing maintenance and will take on its own character and due to individual nature of a rusted item – each piece is different. It is recommended that corten is hosed down following any bird droppings etc falling onto the items.

Please note that Corten will continuously change with heat, moisture and age. Rusted finishes will leach onto surrounding surfaces.

Weight (solid sheet – no cutouts)

1.6mm – 12.56kg / m2

3.0mm – 23.55 kg / m2

Gavlvabond

(Powdercoated)

Standard thickness selection –

1.6mm & 3.0mm

Maximum sheet size –

3000x1500mm

Galvabond is galvanized mild steel sheet, which offers better corrosion resistance than regular mild steel. Following laser cutting, or cutting in general, the edges are still prone to some corrosion. This is due to the edges being cut, and the galvanized surface being broken. When powdercoated the entire panel has much better corrosion resistance, however the edges can still have some corrosion come through the powdercoat over time. If you are in coastal environments, or if the product is going to be in full weather we would suggest an aluminium material.

Weight (solid sheet – no cutouts)

1.6mm – 12.56kg / m2

3.0mm – 23.55 kg / m2

Aluminium

(Powdercoated)

Standard thickness selection –

3.0mm

Maximum sheet size –

3000x1500mm

Aluminium offers the best combination of strength, weight and corrosion resistance. When used as a substrate for a powdercoated finish aluminium offers the best long term results. It’s non ferrous nature mean that it is incapable of rusting, and there is no chance of it corroding should scratch or chip the surface. For best results, and in harsh coastal environments we recommend that you follow our care and maintenance instructions.

Weight (solid sheet – no cutouts)

3.0mm – 8.4 kg / m2

PO Box Designs also work with Stainless Steel, Copper, Brass, Timber and Acrylics.

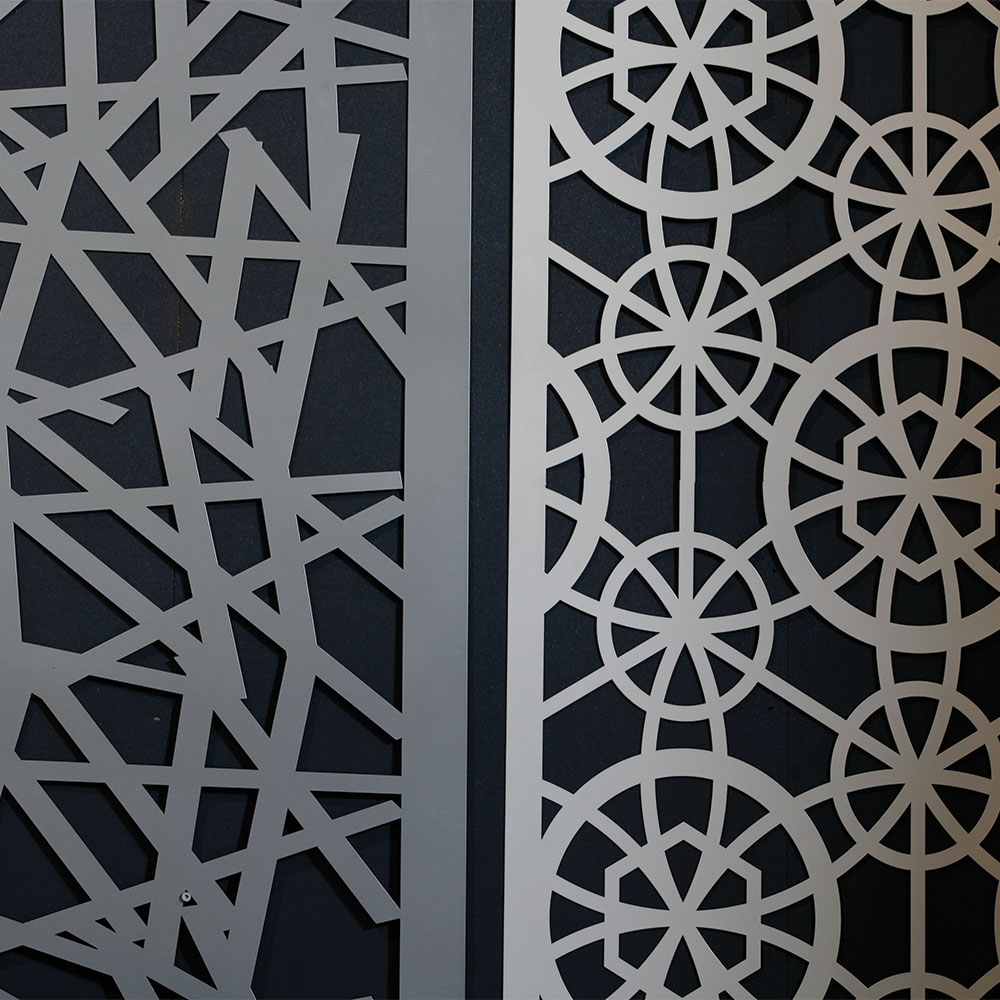

Standard Finish Options

Our standard selection of finishes includes rusted and powdercoated options. To discuss custom requirements please contact us.

Rust

Every rusted piece will be different, some different tones shown below.

Powdercoat

The PO Box Designs standard Powdercoat colour selection is provided below:

Please note:

- Colours will look different on screen to the actual product.

- If you require a colour not shown above please contact us.

- Visit our Installation, Care & Maintenance page to see the care and maintenance guidelines.

- Powdercoat colours cannot be matched to paint colours. Unlike paints which can be tinted to thousands or shades and finishes, powder coatings are formulated and factory produced. Powder coatings cannot be tinted successfully since the solid particles of each colour do not blend together, causing a mottled, speckled look when two different colours are mixed together.

- Should you be matching a powdercoat colour to painted or powdercoated surfaces on your project there will be some variation. While the colour name may be the same the batch, application thickness, material and age can all have an effect on how the colour matches.

- Not all colours behave the same during application or performance on site. Generally, light colours are ideal for more applications than other colour groups.Light colours absorb little light because the white pigments help reflect the light. This reduces the heat up effect on parts. Dark colours absorb light and hence heat far more readily, which explains why dark cars are hotter than white cars in the sun. If heat is an important element in the design or use of your product, the effects of light and dark colours are an important consideration.Bright colours behave differently again as they not only absorb light and remit this as brightness, the pigments are more readily damaged by ultra violet light reducing the life of the colour. Bright colours that include reds, oranges, greens and blues are recommended for applications where colour retention is not critical such as playground equipment and furniture